Full stop

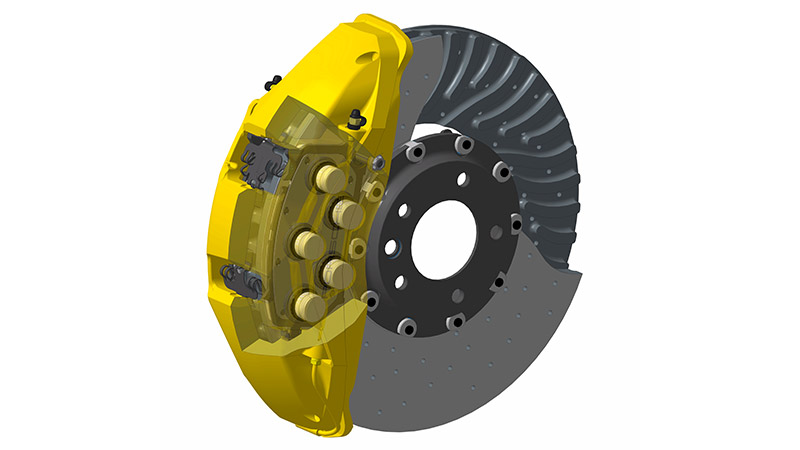

The ten-piston brake calipers on the front axle of the

In spite of all foresight, sometimes only a spirited stomp on the brake pedal will do the trick. What happens then in a

“In true sports cars, the engine and brake power belong together like yin and yang,” says Donatus Neudeck, head of brakes, hydraulics, and actuation systems at

The goal of the developers is to provide the best braking performance and driving dynamics in the segment for every model line. That applies for the

“The final design of the brake system derives from our fading brake cycle, which is one of the most sophisticated in the whole industry,” explains Alexander Prahst, head of development for ceramic brakes. The extreme test takes place on the high-speed circular track in Nardò, Italy, and consists of twenty brakings. The testers accelerate the car from 90 to 230 km/h. Then they hit the brakes.

“After fifteen brakings, the discs reach temperatures of up to 750 degrees Celsius. To test the cooling efficiency, we let the brakes cool down to 150 degrees between the fifteenth and sixteenth brakings. With the last five brakings, we then check whether their frictional coefficient has changed or whether the brakes work with the same cool composure as at the beginning of the test,” says Prahst.

With the new 419 kW (570 hp) and up to 2,900-kilo (fully loaded)

In combination with the standard 420 x 40–millimeter ceramic discs with aluminum brake pots, the new development permits a drastic enlargement of the pad surface to 165 cubic centimeters. “In combination with the also new friction coating on the brake disc, it enables extremely uniform, consistently high friction,” explains Prahst. At the same time, it was possible to reduce the weight of the brake disc from 9.8 to just under 8.5 kilograms. “Size and weight are clearly conflicting objectives. In our high-performance variants, we therefore rely exclusively on the

Moreover, the engineers designed the aerodynamics and axles to allow as much cooling air as possible into the center of the brake pot. Internally vented brake discs direct the heat via unidirectional internal cooling channels with exceptional efficiency. Neudeck illustrates just how decisive this is with an example: “When braking to a stop from top speed, the friction heat generated by the

Performance, noise, and comfort present additional conflicts. “The vibration of the disc causes it to act like a speaker that reflects sounds.” In road use, customers do not accept the type of ambient noise tolerated while racing on a track. That’s why we work together with the manufacturers to develop pads that unite braking performance with noise requirements,” says Neudeck.

Aside from these differences in the details, brake development in motor racing and

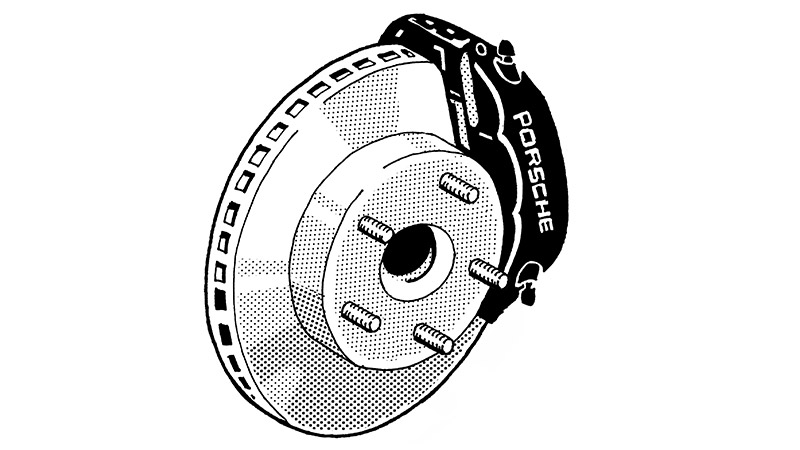

Another step towards greater brake power was marked by the axially mounted aluminum fixed caliper, which became the standard of the 964 (from 1988) and 993 (from 1993) generations of the 911. The use of 17-inch wheels in the 964 enabled a major upsizing of the brake system. The technology was once again driven by the racing department.

In the Group 5

The different

“

After 2021, the use of copper in brake pads will be prohibited in the United States. At present, the copper content in brake pads is up to 35 percent—thanks to its high heat absorption and homogeneous dispersion, the material has played a major role in high-performance brake pads to date. “We essentially had to start from scratch on that point,” says Neudeck. “We’ve now found some very interesting alternatives, however, and will likely fulfill the new standards well ahead of time.” The next brake highlight from

By Christoph Reifenrath

Photos by Rafael Krötz

The world is a disc

From the 356 to the Cayenne : Milestones in brake development

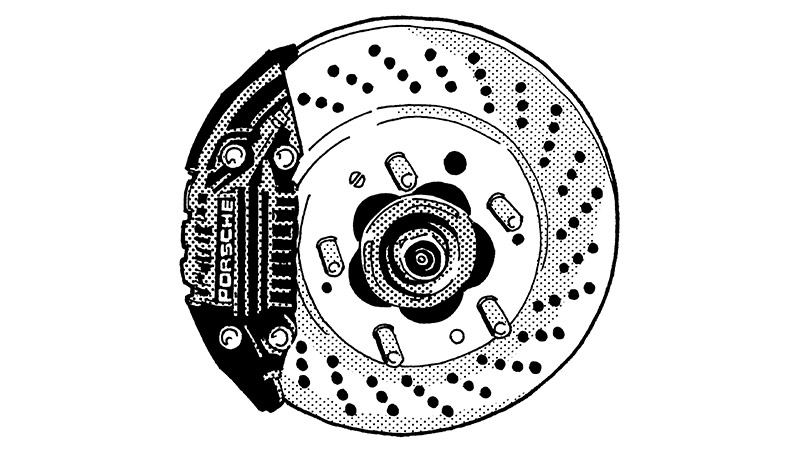

2015

Ten-piston brake calipers are being used for the first time on the front axle of the

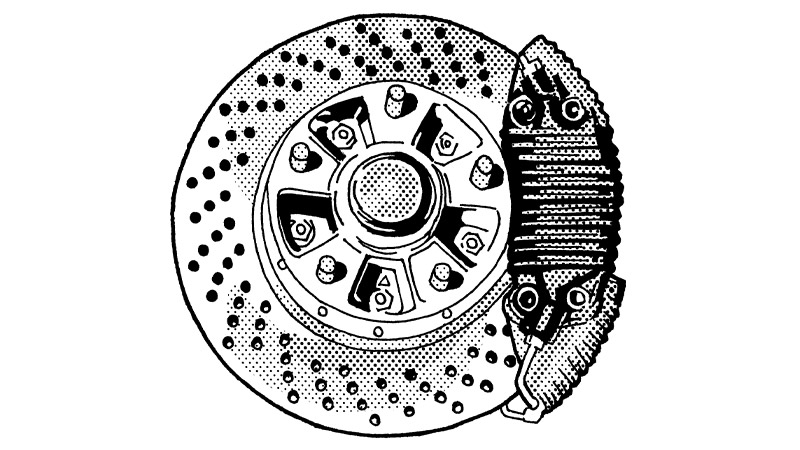

2001

The PCCB (

1996

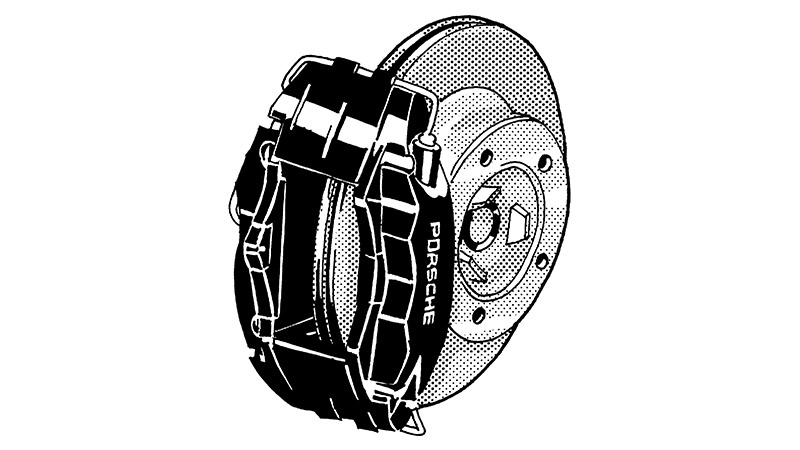

Monobloc aluminum brake calipers come standard in the first

1983

Anti-lock brakes (ABS) first appear as an option for the 928 S. The system prevents the wheels from locking during full braking—the car retains its steerability.

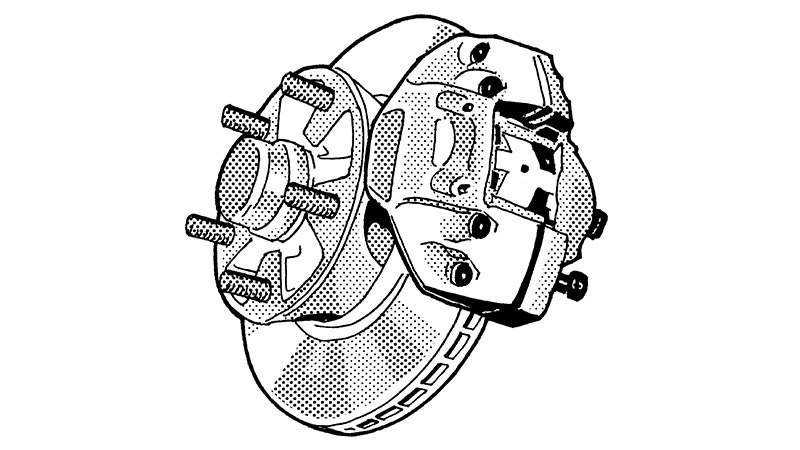

1977

Four-piston brake calipers ensure that the brake performance in the 911

1974

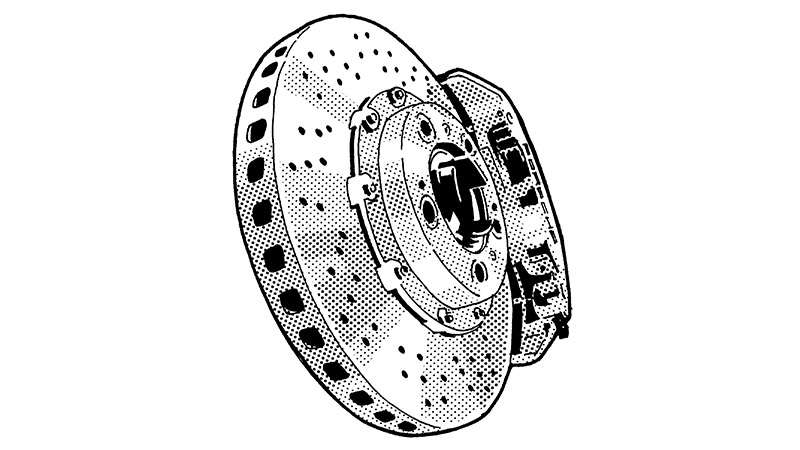

Cross-drilled brake discs are a part of the specific equipment of the 911

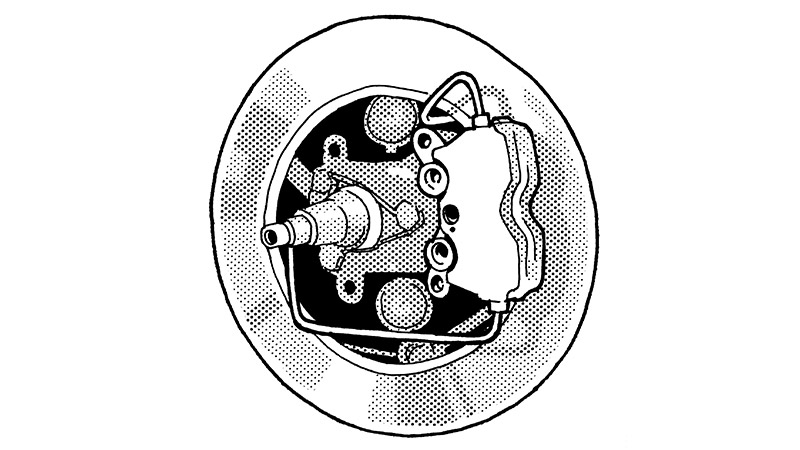

1966

Internally vented brake discs make their premiere as standard equipment in the 911 S—front and rear. The cooling openings between the friction surfaces dissipate the heat generated while braking.

1962

Annular disc brakes are used in the 356 B

Illustrations by Bernd Schifferdecker